In the world of industrial machinery, the relentless transfer of power from a motor to a driven component is a fundamental process. This power transmission must be efficient, reliable, and capable of withstanding incredibly harsh conditions. At the heart of many critical systems, from steel mills to mining operations, lies an unsung hero: the heavy-duty drum gear coupling. This robust component is engineered to handle the most demanding applications where high torque, misalignment, and harsh environments are the norm. This guide delves into what makes this coupling unique, where it’s used, and how to ensure it delivers maximum service life.

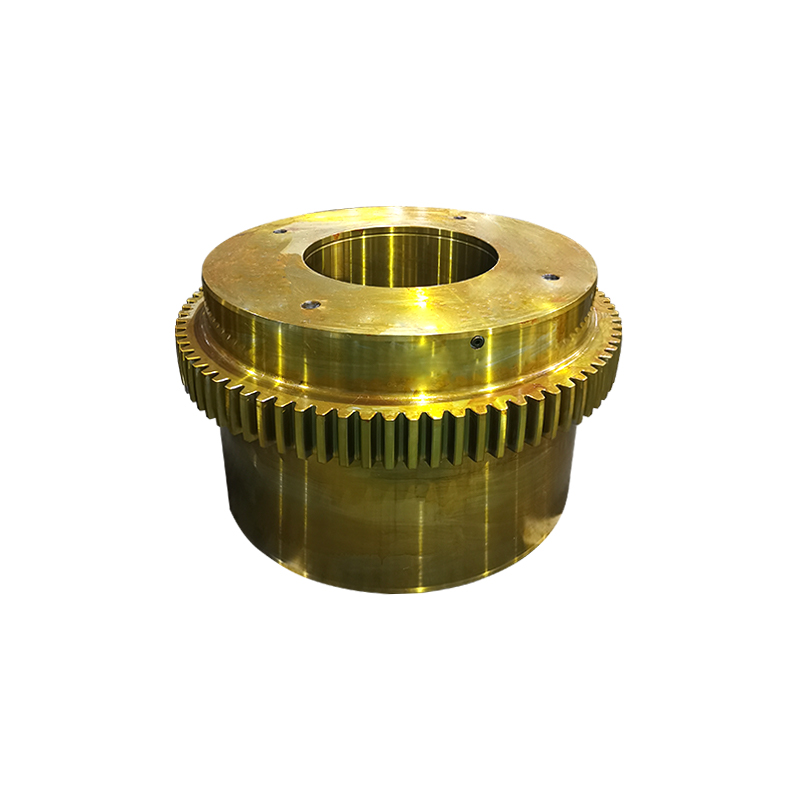

A drum gear coupling is a mechanically flexible coupling designed to connect two rotating shafts while accommodating misalignment and transmitting high torque. Its name comes from its distinct design:

The magic of its flexibility lies in the interaction between the hub and sleeve teeth. As the connected shafts experience inevitable minor angular misalignment or parallel offset, the gear teeth allow for a slight sliding and rocking motion, preventing harmful forces from being transmitted to the connected equipment.

Why choose a drum gear coupling over other types for severe service? The design offers several distinct benefits for high-torque transmission:

Exceptional Misalignment Capacity: Drum gear couplings can accommodate significant angular and parallel misalignment, far more than many other coupling types. This inherent flexibility protects bearings and seals in both the motor and driven equipment from premature wear caused by shaft misalignment.

High Torque Density: Their design, with multiple teeth engaged simultaneously, provides an enormous surface area for transmitting power. This allows them to handle very high torque loads in a relatively compact package, making them ideal for space-constrained installations.

Torsional Rigidity: Unlike flexible elastomeric couplings, gear couplings are torsionally stiff. They do not exhibit backlash or wind-up under load, ensuring precise synchronization between the connected shafts. This is crucial for applications like rolling mills or large synchronous motors.

Durability and Long Service Life: Constructed from high-strength alloy steels and often through-hardened or case-hardened, these couplings are built to last. When properly selected, installed, and maintained, they can endure years of continuous operation in punishing environments.

Maintainability: Most standard drum couplings are designed for easy maintenance. They can be disassembled, inspected, and reassembled without requiring axial movement of the connected equipment, a significant advantage for large machinery where moving a multi-ton motor is a major undertaking.

Heavy-duty drum gear couplings are the workhorses of industry. You will find them wherever massive power needs to be transferred reliably:

The performance and longevity of a drum gear coupling are almost entirely dependent on proper installation and a disciplined maintenance regimen.

Installation:

Maintenance:

Choosing the correct heavy-duty drum gear coupling requires careful analysis:

By understanding the engineering principles, applications, and maintenance needs of heavy-duty drum gear couplings, plant managers, maintenance engineers, and reliability professionals can make informed decisions that enhance machinery uptime, reduce maintenance costs, and ensure the smooth, powerful transmission of energy that drives modern industry.

We have a strong R&D team, and we can develop and produce products according to the drawings or...

We have two of our own casting foundries and one CNC machining factory. So we can offer the best price...

We have our own testing lab and the advanced and complete inspection equipment, which can...