In the realm of industrial power transmission, the heavy-duty drum gear coupling plays a vital role in connecting rotating shafts while transmitting torque efficiently between machines. It is widely used in steel mills, cement plants, mining equipment, marine propulsion, and other demanding industrial environments where durability and reliability are essential.

However, even the most robustly engineered coupling requires consistent care to maintain its performance. Neglecting maintenance can lead to premature wear, vibration, and costly downtime.

Before delving into maintenance, it’s important to briefly understand what a heavy-duty drum gear coupling is and how it works.

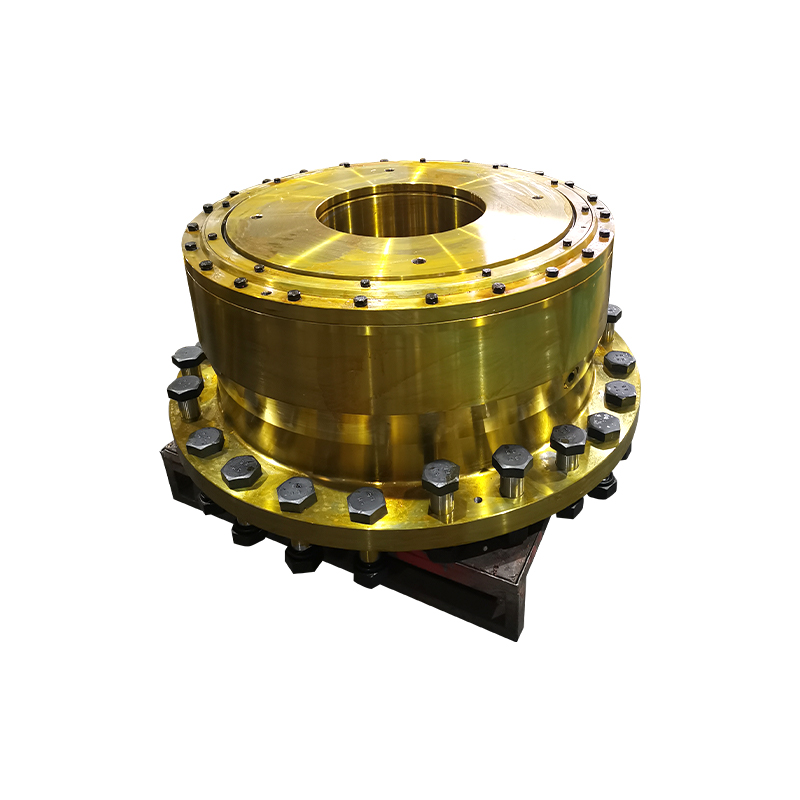

A drum gear coupling consists of two hubs with external teeth (gears) and two sleeves with internal teeth that engage the hubs. The “drum” refers to the crowned tooth design, which allows for angular misalignment between the connected shafts. The assembly transmits torque through the meshing teeth while accommodating limited misalignment and axial movement.

Due to the nature of its design, this coupling type is exposed to continuous mechanical stress and requires lubrication to reduce friction between the meshing gears. Regular inspection and proper maintenance ensure the coupling performs optimally throughout its operational life.

The maintenance of a heavy-duty drum gear coupling directly impacts machinery reliability and service life. Poorly maintained couplings can result in:

By following a structured maintenance plan, organizations can minimize unplanned shutdowns, extend equipment life, and reduce repair costs.

A well-structured maintenance schedule should combine visual inspections, lubrication routines, and mechanical checks. The frequency depends on the operating environment, load conditions, and rotational speed, but a general guideline can be categorized as follows:

Establishing a detailed maintenance log is also beneficial. Documenting inspection results helps track wear trends and predict replacement timelines before failure occurs.

Proper lubrication is the single most important factor in maintaining a heavy-duty drum gear coupling. The lubricant forms a protective film that minimizes metal-to-metal contact, reduces wear, and dissipates heat.

Key lubrication practices include:

Use high-quality gear grease or oil that can withstand the operational temperature and load. For heavy-duty industrial environments, grease containing extreme pressure (EP) additives is typically recommended. These additives enhance the lubricant’s ability to resist high torque and shock loads.

In high-temperature environments, synthetic lubricants or specialty greases may be required to maintain viscosity and prevent oxidation.

Check lubricant levels periodically and top up as needed. A coupling that operates with insufficient lubrication is prone to excessive friction, leading to premature wear and overheating.

Re-lubrication frequency depends on speed, load, and environmental conditions. As a general rule:

Inspect seals for cracks or leaks regularly. Damaged seals allow lubricant to escape and contaminants such as dust, water, or chemicals to enter—accelerating gear deterioration. Replacing seals promptly is a small investment that prevents major failures later.

Proper alignment during installation and throughout the coupling’s life is essential. Misalignment increases load on the gear teeth, leading to uneven wear and vibration.

Recommended practices include:

In addition, ensure that the coupling is balanced to minimize dynamic forces, particularly in high-speed applications. Imbalance can cause premature bearing wear and shaft fatigue.

Gear tooth wear is one of the most common issues in a heavy-duty drum gear coupling. During scheduled maintenance:

If damage is detected, replacement of the affected hub or sleeve may be necessary. Minor wear can sometimes be corrected by regrinding, but this should only be done by qualified technicians.

All fasteners securing the coupling components must be torqued according to manufacturer specifications. Loose bolts can lead to unbalanced rotation or disassembly during operation.

During inspection:

A heavy-duty drum gear coupling’s performance can be affected by its operating environment. Therefore, maintenance should also account for external factors:

By adapting maintenance intervals and materials to suit environmental conditions, operators can significantly enhance reliability.

If a coupling or spare parts need to be stored before installation:

Proper storage ensures that the coupling remains ready for immediate and reliable use.

Even experienced maintenance teams sometimes make errors that can shorten a coupling’s service life. The most frequent mistakes include:

Training staff on correct coupling maintenance techniques is an effective way to prevent these issues.

Regular maintenance of a heavy-duty drum gear coupling offers numerous advantages:

Ultimately, disciplined care ensures that the coupling continues to deliver stable torque transmission and reliability, even under extreme loads.

A heavy-duty drum gear coupling is designed for endurance, but it relies on proactive maintenance to deliver peak performance over time. By implementing a structured maintenance program—covering lubrication, alignment, inspection, and environmental adaptation—operators can significantly extend coupling life, reduce mechanical failures, and enhance system reliability.

In the end, coupling maintenance is not just about preventing breakdowns—it’s about ensuring the efficiency, safety, and longevity of the entire power transmission system. A small investment in routine care today can save substantial time and cost tomorrow.

We have a strong R&D team, and we can develop and produce products according to the drawings or...

We have two of our own casting foundries and one CNC machining factory. So we can offer the best price...

We have our own testing lab and the advanced and complete inspection equipment, which can...